Auto Industry at a Crossroad

The auto industry could soon find itself navigating some bumpy roads due to a looming shortage of rare earth magnets. These magnets, mostly sourced from China, play a crucial role in production, powering everything from automatic transmissions to sophisticated sensor systems. Earlier this month, a coalition of automotive giants like Volkswagen, Hyundai, and General Motors voiced their concern to the U.S. administration about the issue. They’ve highlighted that if the supply chain disruption continues, car production lines may grind to a halt, potentially leaving dealerships empty and production workers idle. Reuters had already shed light on how this shortage could ripple through the system, affecting countless components such as alternators, cameras, and even seat belts.

Trade Woes

America’s relationship with China is like a never-ending roller coaster ride, and the recent trade skirmish only adds extra loops. This drama kicked off when China put a lid on its rare earth magnets export on April 4. The U.S. expected the taps to reopen after mid-May, following a temporary diplomatic ceasefire, but it hasn’t been smooth sailing. U.S. Trade Representative Jamieson Greer recently mentioned that the steady flow of these crucial minerals has yet to resume, echoing concerns across the auto sector.

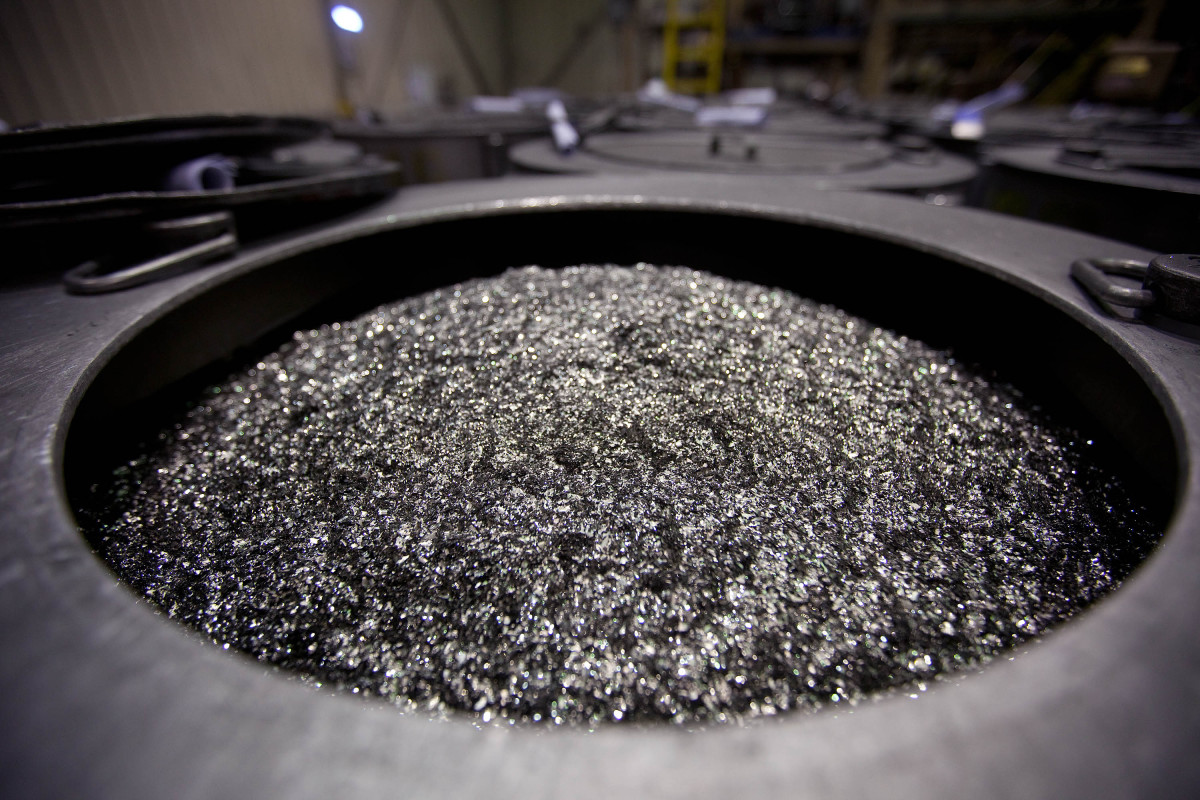

The Chinese embassy states that America is pulling no punches in its semiconductor exports, causing friction. Meanwhile, some Chinese companies halting production is only making matters worse. Reuters also reports that China controls a whopping 90% of the world’s capacity for processing these magnets. While there’s a hint of optimism with small factories set to kickstart production in states like Texas and South Carolina, it’s going to take a while to build the momentum needed to meet demand.

Future Outlook

The geopolitical tangles over rare earth supply affect more than just the U.S. Automakers across Europe and even India feel the pinch. Germany’s Bosch is feeling the heat, dealing with bureaucratic hurdles in securing export licenses from China. The EU is scrambling to boost its local mining efforts, tired of being at the mercy of one primary supplier. It’s not just about keeping the wheels of industry turning—it’s about securing an essential supply chain.

In the meantime, industry players are bracing for a potentially rocky ride. The scarcity of these magnets means slower car production, and ultimately, fewer cars making it off the production line. The reliance on China’s monopoly for rare earth minerals underscores the importance of diversifying sources globally. For now, the automotive giants play the waiting game, with factories and workers caught in the mix until solutions materialize. It’s a real test of resilience for the auto sector, highlighting the critical link between global trade dynamics and the everyday car on the road.

Electric M3 Unveiled

Bohema Sets New Bar

Ford Recall Struggles

EV Charging Evolution

Rimac's E30 V10 Dream